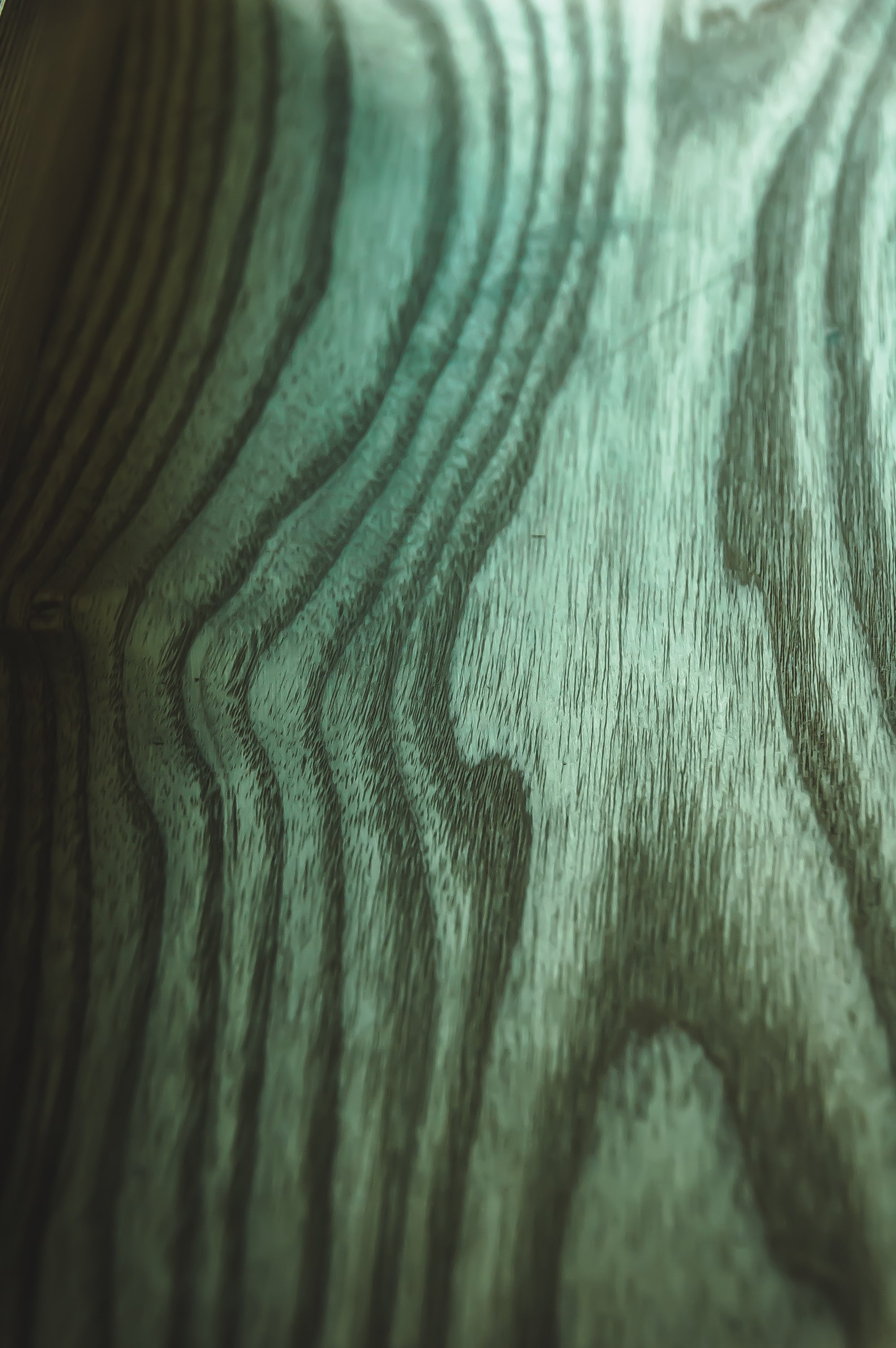

The next stage of the construction is the frame which the shelf is attached to and would subsidquently be attached to the wall. I opted to use Ash simply because I had a small piece left over from a previous project that I could do something with.

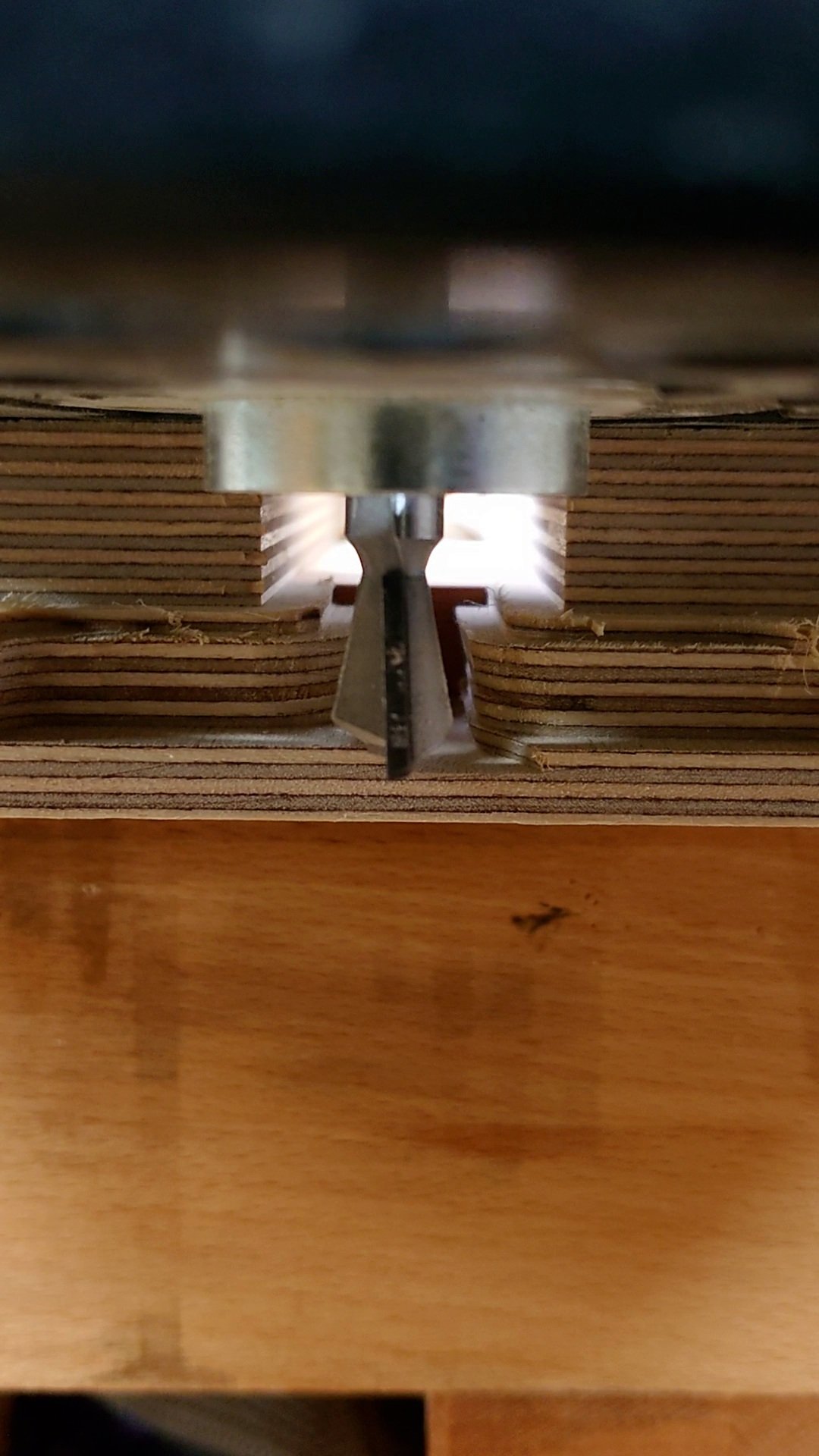

Dovetails

The frame is constructed with traditional hand cut dovetails purely for asthetics but it does provide strength to the joints with the prospective of be able make wider shelves with support for future projects.

The dovetail joint probably pre dates written history. Some of the earliest known examples of the dovetail joint are in ancient Egyptian furniture entombed with mummies dating from First Dynasty, the tombs of Chinese emperors, and a stone pillar at the Vazhappally Maha Siva Temple in India. The dovetail design is an important method of distinguishing various periods of furniture

You may hear the dovetail joint refered to sometimes as a swallowtail joint, a culver tail joint (culver also means 'dove'), or a fantail joint.

The dovetail joint is very strong because of the way the 'tails' and 'pins' are shaped. This makes it difficult to pull the joint apart and virtually impossible when glue is added. This type of joint is used in box constructions such as drawers, jewellery boxes, cabinets and other pieces of furniture where strength is required. It is a difficult joint to make manually, requiring skilled workmanship.